Study on Machinability Issues of Hard to Machining Inconel 718 - A Review

DOI:

https://doi.org/10.22452/mjs.vol44no2.10Keywords:

Inconel 718, Microstructure, Machinability, Tool wear, NanofluidsAbstract

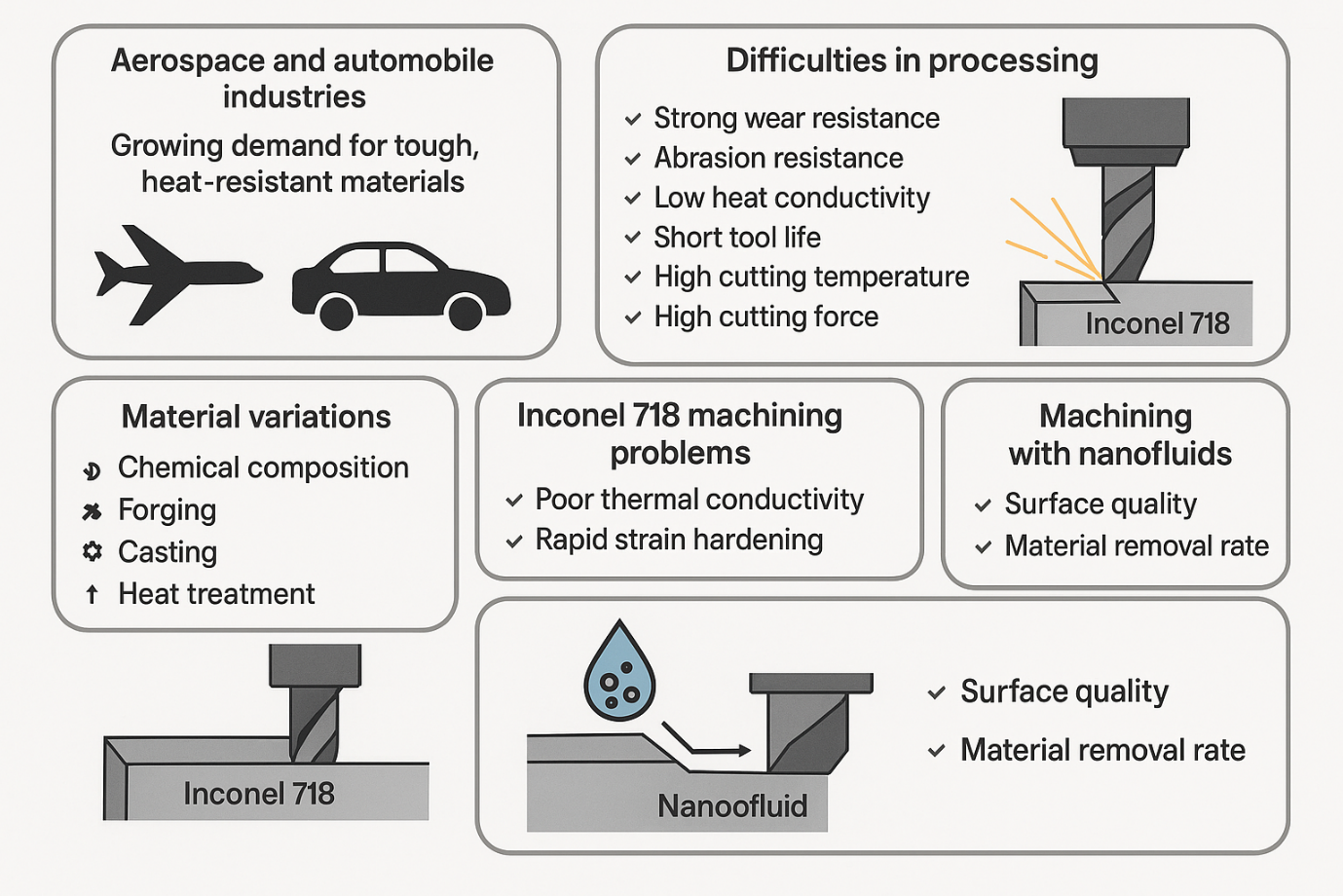

In the aerospace and automobile industries, there has been a recent growing demand for tough and heat-resistant materials. Processing these materials is difficult, primarily due to their mechanical properties, which include strong wear resistance, abrasion resistance, and low heat conductivity. This results in short tool lifetimes and high cutting temperatures and forces. Variations in machinability may be brought on by changes in material microstructures brought on by changes in chemical composition, forging methods, casting, and heat treatment. Because of their remarkable greater efficiency and effectiveness, Inconel 718 nickel superalloys are employed in numerous automotive, marine, and aviation applications. In contrast, Inconel 718's poor thermal conductivity and quick strain hardening made fabrication difficult and compromised the surface's machining ability. This study examines Inconel 718 machining problems, and the issue of dry machining and machining with nanofluids, which demonstrates advancements in research on improving surface quality and material removal rate by reviewing the properties of alumina (Al2O3)-based nanofluids.

Downloads

References

Amrita, M.; Srikant, R. R.; Sitaramaraju, A. V. (2014). Performance Evaluation of Nanographite-Based Cutting Fluid in Machining Process. Mater. Manuf. Process., 29 (5), 600–605. https://doi.org/10.1080/10426914.2014.893060.

Amrita, M.; Srikant, R. R.; Sitaramaraju, A. V.; Prasad, M. M. S.; Krishna, P. V. (2013). Experimental Investigations on Influence of Mist Cooling Using Nanofluids on Machining Parameters in Turning AISI 1040 Steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 227 (12), 1334–1346. https://doi.org/10.1177/1350650113491934.

Anthony Xavior M, Duchosal A, Jeyapandiarajan P. (2018). Experimental Investigation on Work Hardening and Residual Stress during Machining of Inconel718. Mater Today Proc;5(5):13301-13308. doi:10.1016/j.matpr.2018.02.322

Chaudhari, S. S.; Chakule, R. R.; Talmale, P. S. (2019). Experimental Study of Heat Transfer Characteristics of Al2O3 and CuO Nanofluids for Machining Application. Mater. Today Proc., 18, 788–797. https://doi.org/10.1016/j.matpr.2019.06.499.

Chaudhari, S. S.; Chakule, R. R.; Talmale, P. S. (2019). Experimental Study of Heat Transfer Characteristics of Al2O3 and CuO Nanofluids for Machining Application. Mater. Today Proc., 18, 788–797. https://doi.org/10.1016/j.matpr.2019.06.499.

Davies MA, Burns TJ, Evans CJ. (2021). On the dynamics of chip formation in machining hard metals. CIRP Ann - Manuf Technol. 46(1):25-30. doi:10.1016/s0007-8506(07)60768-9

Endrino JL, Fox-Rabinovich GS, Gey C. (2006). Hard AlTiN, AlCrN PVD coatings for machining of austenitic stainless steel. Surf Coatings Technol. 200(24):6840-6845. doi:10.1016/j.surfcoat.2005.10.030

Fox-Rabinovich GS, Kovalev AI, Aguirre MH. (2009). Design and performance of AlTiN and TiAlCrN PVD coatings for machining of hard to cut materials. Surf Coatings Technol.;204(4):489-496. doi:10.1016/j.surfcoat.2009.08.021

Gupta K, Paulo Davim J. (2020). High-speed machining. High-Speed Mach.; 41:1-311. doi:10.1016/C2017-0-02542-9

Gupta, M. K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hegab, H.; Khan, A. M.; (2019). Collado, A. G.; Pruncu, C. I.; et al. Performance Evaluation of Vegetable Oil-Based Nano-Cutting Fluids in Environmentally Friendly Machining of Inconel-800 Alloy. Materials (Basel)., 12 (7). https://doi.org/10.3390/ma12172792.

Huang, W. T.; Chen, J. T. (2020). Application of Intelligent Modeling Methods to Enhance the Effectiveness of Nanofluid / Micro Lubrication in Microdeep Drilling Holes Machining. J. Adv. Mech. Des. Syst. Manuf., 14 (7), 1–26. https://doi.org/10.1299/jamdsm.2020jamdsm0099.

Iuliana BC. (2015). Factors-influencing-surface-integrity-in-hard-machining-of-steels-A-review.doc. Int J Sci Eng Res.;6(5):38-43.

Khalil, A. N. M.; Ali, M. A. M.; Azmi, A. I. (2015). Effect of Al2O3 Nanolubricant with SDBS on Tool Wear During Turning Process of AISI 1050 with Minimal Quantity Lubricant. Procedia Manuf. 2(February),130–134. https://doi.org/10.1016/j.promfg.2015.07.023.

Kim EJ, Lee CM. (2019). A study on the optimal machining parameters of the induction assisted milling with Inconel 718. Materials (Basel). 12(2). doi:10.3390/ma12020233

Kramar D, Kopač J. (2009). High-pressure cooling in the machining of hard-to-machine materials. Stroj Vestnik/Journal Mech Eng.55(11):685-694.

Krishna, P. V.; Parimala, N. (2019). Effectiveness of Coconut Oil Based Nanofluids in Machining of Steel.2 (1), 49–57.

Mani, N. K.; Mathew, C.; Kallanickal, P. M. (2015). Optimization of Cutting Parameters & Nanoparticle Concentration in CNC Turning of EN8 Steel Using Al2O3 Nanofluids as Coolant. Int. J. Eng. Trends Technol. 29 (6), 290–294. https://doi.org/10.14445/22315381/ijett-v29p254.

Öndin, O.; Kıvak, T.; Sarıkaya, M.; Yıldırım, Ç. V. (2020). Investigation of the Influence of MWCNTs Mixed Nanofluid on the Machinability Characteristics of PH 13-8 Mo Stainless Steel. Tribol. Int.148.https://doi.org/10.1016/j.triboint.2020.106323.

Parida AK, Maity KP. (2016). An Experimental Investigation to Optimize Multi-Response Characteristics of Ni-Hard Material Using Hot Machining. Adv Eng Forum.16:16-23. doi:10.4028/www.scientific.net/aef.16.16.

Pasam, V. K.; Srikant Revuru, R.; Gugulothu, S. (2018). Comparing the Performance & Viability of Nano and Microfluids in Minimum Quantity Lubrication for Machining AISI1040 Steel. Mater. Today Proc. 5 (2), 8016–8024. https://doi.org/10.1016/j.matpr.2017.11.486.

Paturi UMR, B. VD, Reddy NS. Progress of machinability on the machining of Inconel 718:A comprehensive review on the perception of cleaner machining. Clean Eng Technol. 2021;5:100323. doi:10.1016/j.clet.2021.100323

Rahman M, Seah WKH, Teo TT. (1997). The machinability of Inconel 718. J Mater Process Technol. 63(1-3):199-204. doi:10.1016/S0924-0136(96)02624-6

Rizvi SA, Ali W, Ahmad M, Delhi N. (2016). SOME STUDY OF MACHINABILITY BY TURNING PROCESS-A. II(6):1-20.

Roy, S.; Ghosh, A. (2014). High-Speed Turning of AISI 4140 Steel by Multi-Layered TiN Top-Coated Insert with Minimum Quantity Lubrication Technology and Assessment of near Tool-Tip Temperature Using Infrared Thermography. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 228 (9), 1058–1067. https://doi.org/10.1177/0954405413514570.

Sahin Y, Sur G. (2004). The effect of Al2O3, TiN and Ti (C, N) based CVD coatings on tool wear in machining metal matrix composites. Surf Coatings Technol. 179(2-3):349-355. doi:10.1016/S0257-8972(03)00802-8

Sharma, A. K.; Singh, R. K.; Dixit, A. R.; Tiwari, A. K.; Singh, M. (2019). An Investigation on Tool Flank Wear Using Alumina/MoS2 Hybrid Nanofluid in Turning Operation; Springer International Publishing, 1. 156-189, https://doi.org/10.1007/978-3-319-99353-9_23.

Sharma, K. A.; Tiwari, A. K.; Dixit, A. R. (2015). Mechanism of Nanoparticles Functioning and Effects in Machining Processes: A Review. Mater. Today Proc., 2 (4–5), 3539–3544. https://doi.org/10.1016/j.matpr.2015.07.331.

Shokrani A, Dhokia V, Newman ST. (2012). Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int J Mach Tools Manuf. 57:83-101. doi:10.1016/j.ijmachtools.2012.02.002

Singh PN, Raghukandan K, Rathinasabapathi M, Pai BC. (2004). Electric discharge machining of Al-10%SiCP as-cast metal matrix composites. J Mater Process Technol. 155-156(1-3):1653-1657. doi:10.1016/j.jmatprotec.2004.04.321

Singh, R. K.; Sharma, A. K.; Bishwajeet; Mandal, V.; Gaurav, K.; Nag, A.; Kumar, A.; Dixit, A. R.; Mandal, A.; Kumar Das, A. (2018). Influence of Graphene-Based Nanofluid with Minimum Quantity Lubrication on Surface Roughness and Cutting Temperature in Turning Operation. Mater. Today Proc.,5 (11), 24578–24586. https://doi.org/10.1016/j.matpr.2018.10.255.

Sreejith PS, Ngoi BKA. (2000). Dry machining: Machining of the future. J Mater Process Technol. 101(1):287-291. doi:10.1016/S0924-0136(00)00445-3

Su Y, He N, Li L, (2007). Refrigerated cooling air cutting of difficult-to-cut materials. Int J Mach Tools Manuf;47(6):927-933. doi:10.1016/j.ijmachtools.2006.07.005

Thakur, A.; Manna, A.; Samir, S. (2020) Multi-Response Optimization of Turning Parameters during Machining of EN-24 Steel with SiC Nanofluids Based Minimum Quantity Lubrication. Silicon, 12 (1), 71–85. https://doi.org/10.1007/s12633-019-00102-y.

Vasu, V.; Reddy, G. P. K. (2012) Effect of Minimum Quantity Lubrication with Al 2O 3 nanoparticles on Surface Roughness, Tool Wear and Temperature Dissipation in achining Inconel 600 Alloy. Proc. Inst. Mech. Eng. Part N J. Nanoeng. Nanosyst., 225 (1), 3–15. https://doi.org/10.1177/1740349911427520.

Venkatesan K, Ramanujam R. (2018) Statistical approach for optimization of influencing parameters in laser assisted machining (LAM) of Inconel alloy. Meas J Int Meas Confed. 89:97-108. doi:10.1016/j.measurement.2016.04.021

Wang ZY, Rajurkar KP. (2000) Cryogenic machining of hard-to-cut materials. Published online:168-175.

Yücel E, Günay M. (2013) Modelling and optimization of the cutting conditions in hard turning of high-alloy white cast iron (Ni-Hard). Proc Inst Mech Eng Part C J Mech Eng Sci. 227(10):2280-2290. doi:10.1177/0954406212471755.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Malaysian Journal of Science

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Transfer of Copyrights

- In the event of publication of the manuscript entitled [INSERT MANUSCRIPT TITLE AND REF NO.] in the Malaysian Journal of Science, I hereby transfer copyrights of the manuscript title, abstract and contents to the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) for the full legal term of copyright and any renewals thereof throughout the world in any format, and any media for communication.

Conditions of Publication

- I hereby state that this manuscript to be published is an original work, unpublished in any form prior and I have obtained the necessary permission for the reproduction (or am the owner) of any images, illustrations, tables, charts, figures, maps, photographs and other visual materials of whom the copyrights is owned by a third party.

- This manuscript contains no statements that are contradictory to the relevant local and international laws or that infringes on the rights of others.

- I agree to indemnify the Malaysian Journal of Science and the Faculty of Science, University of Malaya (as the publisher) in the event of any claims that arise in regards to the above conditions and assume full liability on the published manuscript.

Reviewer’s Responsibilities

- Reviewers must treat the manuscripts received for reviewing process as confidential. It must not be shown or discussed with others without the authorization from the editor of MJS.

- Reviewers assigned must not have conflicts of interest with respect to the original work, the authors of the article or the research funding.

- Reviewers should judge or evaluate the manuscripts objective as possible. The feedback from the reviewers should be express clearly with supporting arguments.

- If the assigned reviewer considers themselves not able to complete the review of the manuscript, they must communicate with the editor, so that the manuscript could be sent to another suitable reviewer.

Copyright: Rights of the Author(s)

- Effective 2007, it will become the policy of the Malaysian Journal of Science (published by the Faculty of Science, University of Malaya) to obtain copyrights of all manuscripts published. This is to facilitate:

- Protection against copyright infringement of the manuscript through copyright breaches or piracy.

- Timely handling of reproduction requests from authorized third parties that are addressed directly to the Faculty of Science, University of Malaya.

- As the author, you may publish the fore-mentioned manuscript, whole or any part thereof, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given. You may produce copies of your manuscript, whole or any part thereof, for teaching purposes or to be provided, on individual basis, to fellow researchers.

- You may include the fore-mentioned manuscript, whole or any part thereof, electronically on a secure network at your affiliated institution, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- You may include the fore-mentioned manuscript, whole or any part thereof, on the World Wide Web, provided acknowledgement regarding copyright notice and reference to first publication in the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers) are given.

- In the event that your manuscript, whole or any part thereof, has been requested to be reproduced, for any purpose or in any form approved by the Malaysian Journal of Science and Faculty of Science, University of Malaya (as the publishers), you will be informed. It is requested that any changes to your contact details (especially e-mail addresses) are made known.

Copyright: Role and responsibility of the Author(s)

- In the event of the manuscript to be published in the Malaysian Journal of Science contains materials copyrighted to others prior, it is the responsibility of current author(s) to obtain written permission from the copyright owner or owners.

- This written permission should be submitted with the proof-copy of the manuscript to be published in the Malaysian Journal of Science

Licensing Policy

Malaysian Journal of Science is an open-access journal that follows the Creative Commons Attribution-Non-commercial 4.0 International License (CC BY-NC 4.0)

CC BY – NC 4.0: Under this licence, the reusers to distribute, remix, alter, and build upon the content in any media or format for non-commercial purposes only, as long as proper acknowledgement is given to the authors of the original work. Please take the time to read the whole licence agreement (https://creativecommons.org/licenses/by-nc/4.0/legalcode ).